Beech 18 Spar Corrosion and Cracking

This page will be updated with more information.

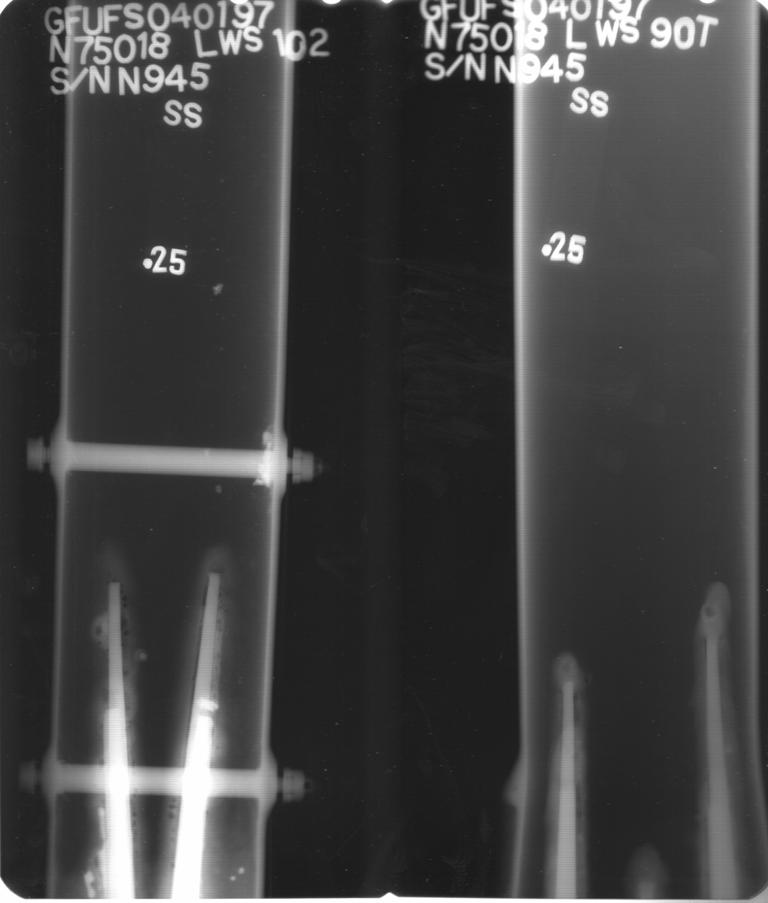

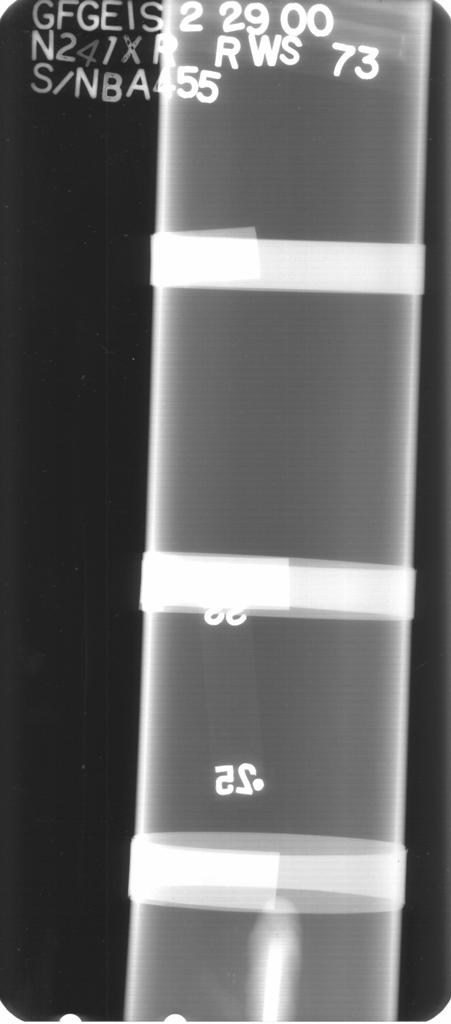

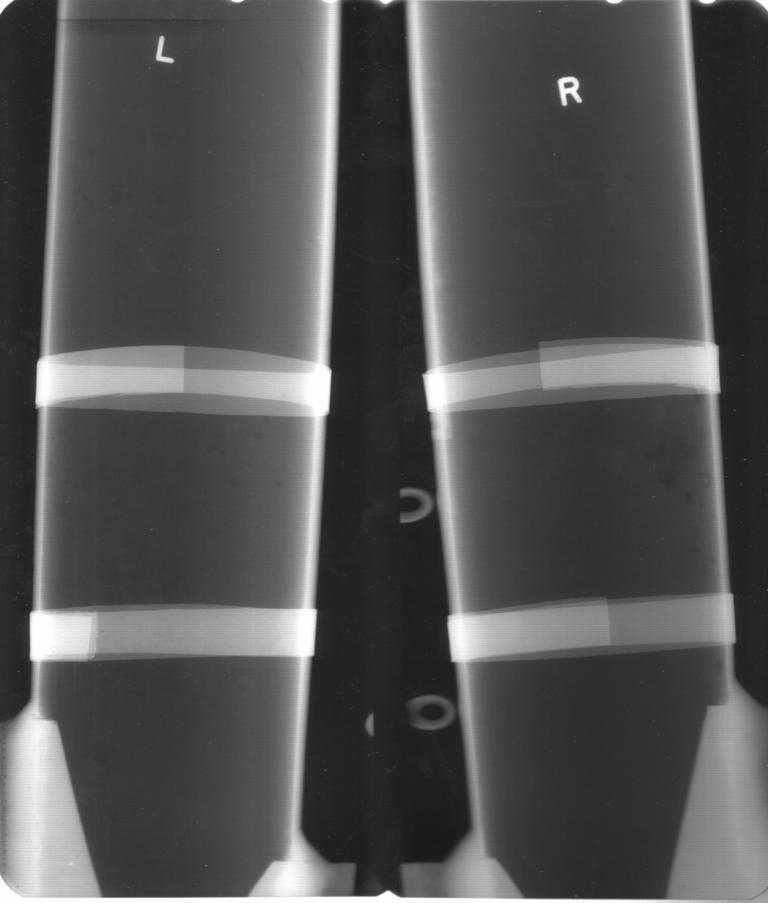

Here are some crude scans of Beech 18 spar x-rays. The x-ray is a great way to see inside the tubing to make sure there is no rust or corrosion.

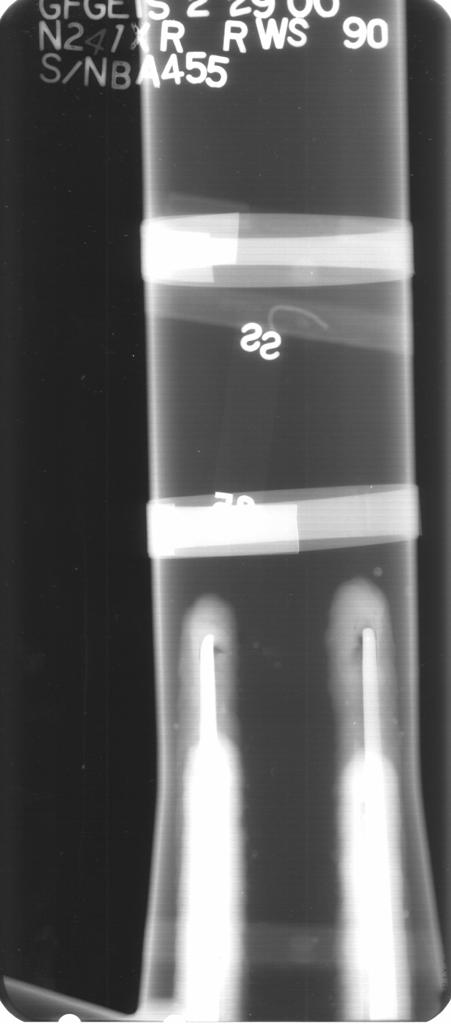

Here is another good example of how x-rays will give you a good look inside the tubing. This is what you want to see; a nice clean spar.

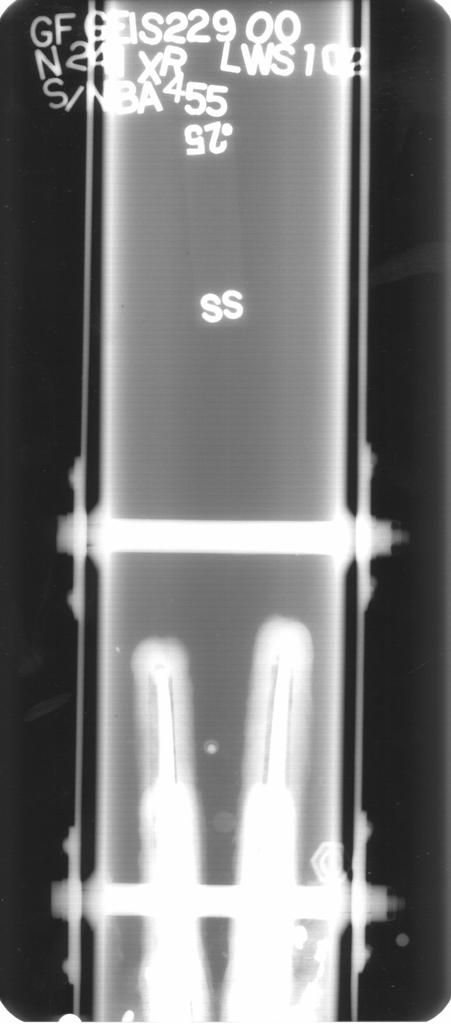

The lighter spots show welding slag on the outside of the tube from the factory.

The dark spots are rust pits inside the tubing. The thinner metal will allow more x-rays to penetrate the metal and hit the film causing the dark spots. The lighter the image the fewer x-rays were able to penetrate. In this case the lead bands placed on the spar tube as a reference for station location will give a lighter band appearance.

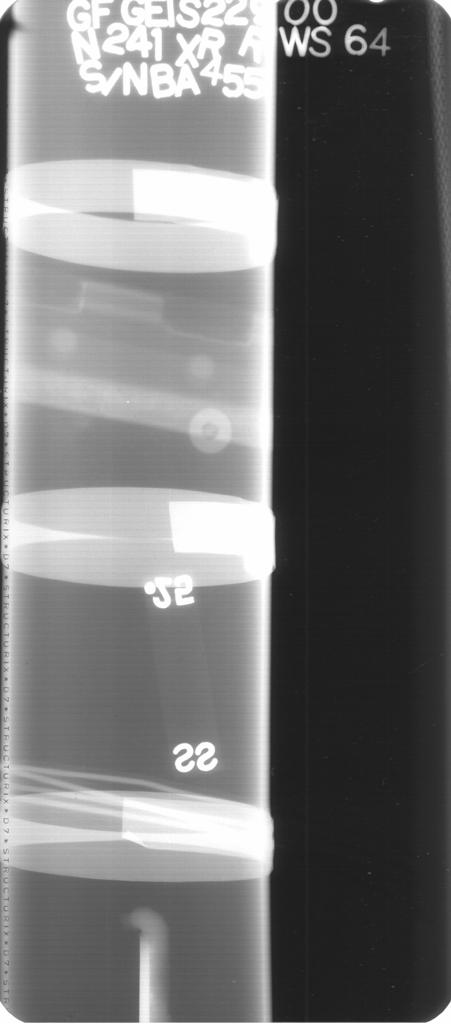

On more extreme cased of internal corrosion you can physically measure the wall thickness degradation on the edges of the tubing in the film. This information is what a DER will need to help determine the remaining strength of the spar.

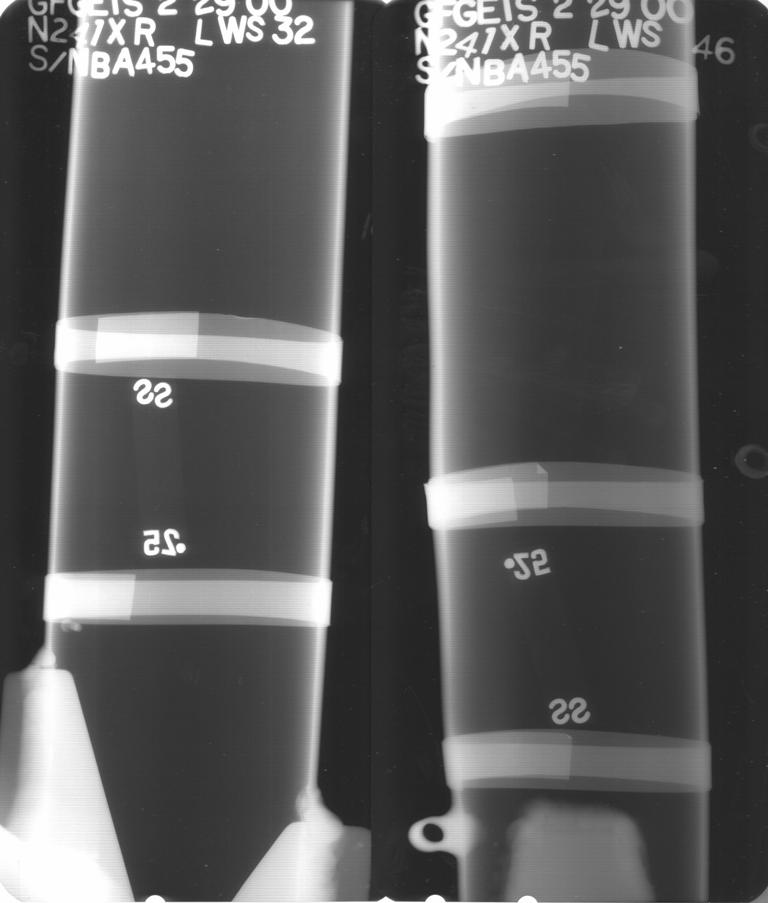

In the shot below notice the dark spots in the welds on the tangs. These are inclusions inside the weld from the factory.